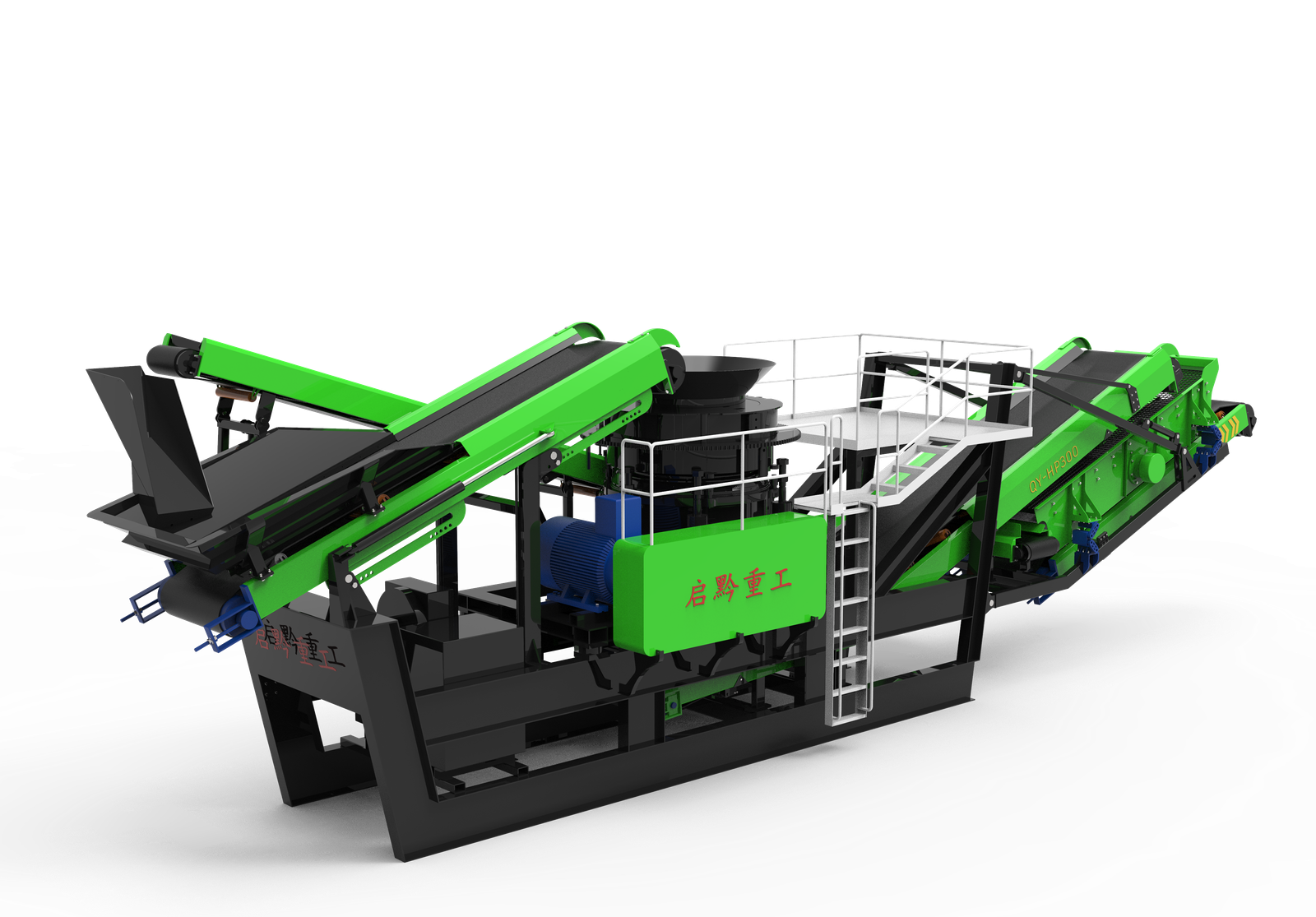

Splicing cone crushing station QY-HP300G

Product parameter table

Product model QY-HP300G

Processing capacity 150-230t/h

Host power 250kw

Total power 298kw

Equipment size (length * width * height) 16800 * 3380 * 3680mm

Feed belt 11kw

Excessive material reflux of 3kw

Main belt 15kw

Feed inlet size 1078mm

Return belt 5.5hw

Finished belt 7.5hw

Hopper capacity 5m3

The total weight of the equipment is 42t

Vibration hanging screen 6kw

Maximum feed particle size<250mm (recommended)

Description

Advantages: The high-efficiency and wear-resistant crusher features a special crushing wall and rolling mortar wall design, supplemented by an arc-shaped cavity and a hydraulic cleaning system, which improves crushing efficiency and effectively reduces the wear of vulnerable parts. The automatic crushing control system adopts the ACS fully automatic crushing control system, which quickly responds to iron overload and automatically releases reset protection, ensuring continuous, timed, and efficient production. Intelligent continuous feeding intelligent system adjustment ensures uniform and stable feeding, avoids host blockage, and effectively improves the continuous and stable working time of the equipment. Advanced hydraulic lubrication system with stable structure and strong adaptability: The main crusher lubrication system and hydraulic system adopt modular design and operate independently, which can achieve protection for oil temperature, flow rate, pressure, power, abnormal power supply, etc. The purpose of the cone crushing station is that the cone crusher is suitable for crushing raw materials in industries such as metallurgy, construction, road construction, chemical engineering, and silicates. According to the principle of crushing and the different particle sizes of the product, it is divided into multiple models. Crushers are widely used in many industries such as mining, smelting, building materials, highways, railways, water conservancy, and chemical engineering. The cone crusher has high crushing ratio, high efficiency, low energy consumption, and uniform product particle size, suitable for medium to fine crushing of various ores and rocks.