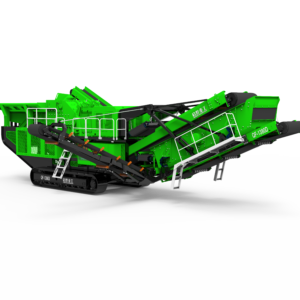

Crawler Mobile Impact Crusher QZ-TV85

Product parameter table

Product model QZ-TV85

Processing capacity 80-200t/h

Host power 220-440kw

Total power 242kw

Equipment size (length * width * height) 14500 * 3200 * 3700mm

Finished conveyor belt 11kw

Transfer feeder 11KW

600mm in feed inlet size

Hopper capacity 3m3

Total weight of equipment 35t

Maximum feed size<40mm (recommended)

Description

Advantages and characteristics

Working principle of the host

“Stone striking stone, stone striking iron” causes stones to collide with stones accelerated by impellers during natural falling, achieving the goal of crushing. When the accelerated stones collide with the naturally falling stones, a vortex is formed, and during the return process, they undergo two more crushing. Therefore, there is little wear on the machine’s counterattack plate during operation. The stones directly fall into the high-speed rotating turntable from the upper part of the machine, and under the action of high-speed centrifugal force, they collide with the target stones distributed around the turntable in an umbrella shape to produce high-speed impact and high-density crushing. After hitting each other, the stones will also rotate again

The screening equipment is controlled to achieve the required particle size. The vortex motion between the disc and the casing causes multiple impacts, friction, and crushing, which are discharged directly from the bottom. Forming a closed loop with multiple special loops, caused by

Capacity upgrade

Increase feed size and production capacity by more than twice, reduce energy consumption of single motor drive by more than 50%, and achieve a sand formation rate of up to 50%~60%. Intelligent continuous feeding

The transmission part adopts a special sealing structure to prevent bearing oil leakage. Special alloy inlay, new fusion welding process, and extremely hard wear-resistant material cutting head greatly extend the service life of the cutting head. The structure is stable and adaptable

Adopting intelligent, integrated, and modular configurations, it has strong on-site passability and can quickly adapt to the use of impact crushing stations in various complex construction environments such as mountains and wetlands

Fabric, gray stone, granite, basalt, diabase, medium hard, extra hard and abrasive materials such as silicon carbide, used in the production of metal and non-metal ores, cement, refractory materials, glass raw materials, cushion materials, asphalt concrete and cement concrete aggregates! The superiority of diamond sand, andesite, and other minerals. Used in conjunction with hydraulic protection jaw breakers, it can handle various metallurgical slag. Suitable for sand and gravel used in construction and road construction. Sintered aluminum vanadium earth has advantages over other types of manual weighing, construction, and various types of materials, and is superior to other types of machines.