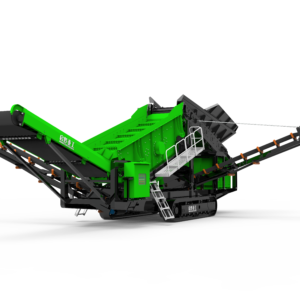

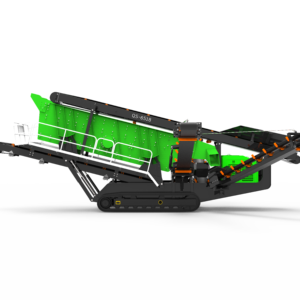

Crawler type mobile horizontal screening station QSP-6200

Product parameter table

Standard configuration: external power supply type is simple and efficient, with high reliability and equipment maintenance

Product model QSP-6200

Processing capacity 220-400h

Main engine power 30k

Total power 69kw

Equipment size (length * width * height) 18500*3960*3900mm

Finished product conveyor belt 1:7.5kw

Finished product conveyor belt 2:5.5kw

Finished product conveyor belt 3:5.5kw

Auxiliary material conveyor belt 7.5kw

Screen box size 6200*1930

Conveyor feeder 7.5kw

Hopper volume 3m

Finished product conveyor belt 4:5.5KW

Total equipment weight 35t

The latest update introduction shall prevail.

Description

Advantages and features

High efficiency and not easy to clog

It has a large processing capacity and high screening efficiency, and it is not easy to clog the screen. The driven wheel on the vibrator is driven by a belt drive to drive three identical gears to generate exciting force, forcing the screen box to move

Strong screening capacity

The three-axis design ensures its high output and high efficiency, making it an ideal choice for screening and processing a large amount of sticky materials, meeting the requirements of fast transfer of fine materials

It is extremely convenient to realize long-distance transportation and transfer operations. Adopting remote intelligent wireless remote control: self-propelled crawler walking, no crane is required, and the flatbed trailer can be directly put on and off by intelligent remote control.

Features of horizontal screening station

The crawler horizontal screening station is designed with three-axis technology, excellent performance, adjustable elliptical eccentric wheel with both linear and circular amplitude, strong screening capacity, and three-axis design to ensure its high output and high efficiency, making it an ideal choice for screening and processing a large amount of sticky materials, meeting the requirements of fine material sorting. It is mainly used for screening finished products such as sand and gravel aggregates. It has strong mobility and good on-site mobility. It can adapt to various complex environments such as mountains and wetlands. It can be equipped with a feeding system to achieve screening efficiency for special materials.