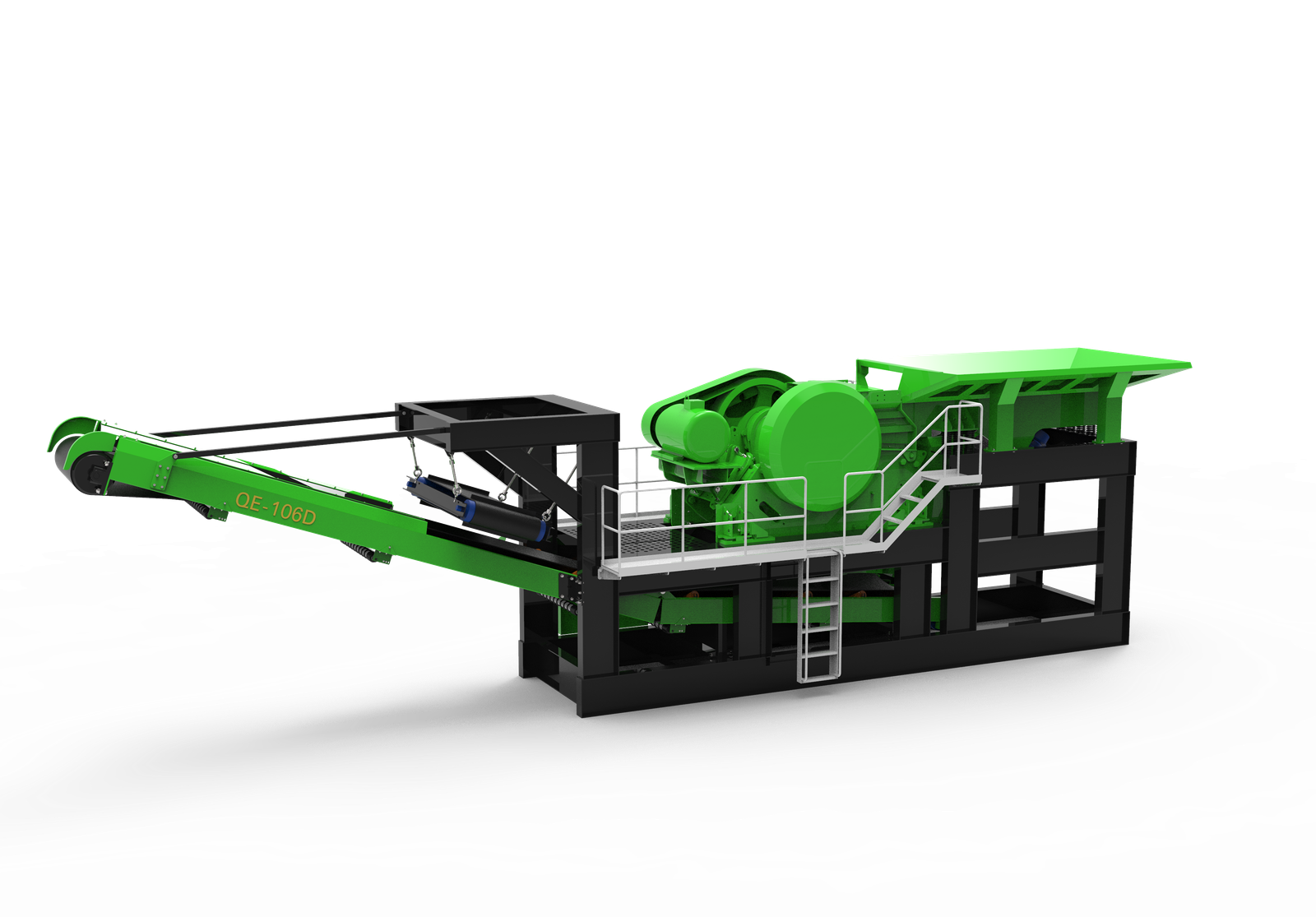

Spliced jaw crushing station QE-106G

Product parameter table

Standard: External power supply type is simple and efficient, with high reliability and low equipment maintenance and operation costs.

Product model QE-106G

Processing capacity 180-400t/h

Main engine power 110kw

Total power 135kw

Equipment size (length*width*height) 14500*3100*3600mm

Iron remover 4kw

Feed hopper 6kw

Main belt 15kw

Feed port size 1060*750mm

Feeding capacity 400/t

Hopper volume 6m3

Total equipment weight 32t

Maximum feed size <700mm (recommended)

Description

Advantages and features

Environmental protection

High-quality movable jaw assemblyThe movable jaw assembly adopts heavy-duty eccentric shaft and heavy-duty bearing, labyrinth seal and centralized lubrication system, with high impact resistance, strong stability and good particle shape of crushed finished products

Adopting European version V-shaped symmetrical cavity and large-angle toggle plate, it greatly improves the effective stroke of the movable jaw, with larger crushing ratio and higher efficiency. Intelligent continuous feeding

Intelligent system adjustment ensures uniform and smooth feeding, avoids blockage of the main engine, and effectively improves the continuous and stable working time of the equipment. Stable structure and strong adaptability

Adopting intelligent, integrated and modular configuration, it has strong on-site passability and can quickly adapt to various complex construction environments such as mountains and wetlands. The purpose of jaw crushing station

With the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable operation, simple maintenance and economical operating costs, jaw crusher is widely used in many departments such as mining (limestone, granite, basalt, diabase, andesite, etc.), smelting, building materials, highways, railways, water conservancy and chemical industries, etc., crushing various materials with compressive strength not exceeding 320MPa, and is the preferred equipment for primary crushing.